Our service –

your benefit.

At S+P it comes to quality in all areas. All areas of S+P prioritise quality and this starts with our staff. More than 270 experienced members of staff ensure that our customers can rely on receiving faultless deliveries at speed, that the goods supplied correspond to the specified standards and that our product range is one step ahead of market requirements.

Certified quality

Our suppliers also have to measure up to our stringent quality requirements. We can’t in any way claim that establishing our international network of expert partners and market-leading manufacturers was easy. But the decades of work have paid off and S+P is now one of the largest stainless steel fastener suppliers and a market leader. Quality that pays.

0

material numbers

0

products

0

DIN standards

0

S+P standards

0

material types

0

article groups

0

product approvals

0

ISO standards

S+P focuses on quality

and of course our customers.

You expect stainless steel products of the highest quality for the best price. So we have entrusted strategic and operational procurement to the best people for the job: ourselves. We can only ensure that we are buying in goods under attractive conditions with concentrated market power. Our sales specialists also analyse all relevant markets on an ongoing basis: from the capital market and the labour and technology market to the procurement and sales market. S+P also offers one of the best ranges in the industry.

We have more than 37 000 stainless steel items. Our wide range includes products such as wood screws, metric screws, safety screws, washers, nuts and even heavy-duty fasteners – all in various versions. Our range also offers a unique dynamism which is aimed specifically at our clientele. We are driven to continually improve ourselves in response to our customers’ special requests. And this setup explains the partnerships we have nurtured over the years with the world’s largest stainless steel producers. They value our knowledge of the latest market trends and quickly develop corresponding products in response.

We have more than 37 000 stainless steel items. Our wide range includes products such as wood screws, metric screws, safety screws, washers, nuts and even heavy-duty fasteners – all in various versions. Our range also offers a unique dynamism which is aimed specifically at our clientele. We are driven to continually improve ourselves in response to our customers’ special requests. And this setup explains the partnerships we have nurtured over the years with the world’s largest stainless steel producers. They value our knowledge of the latest market trends and quickly develop corresponding products in response.

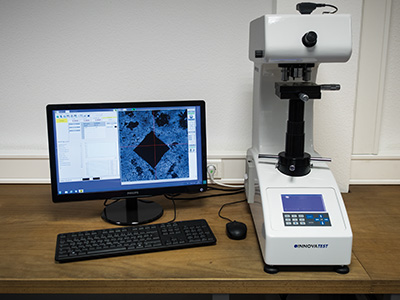

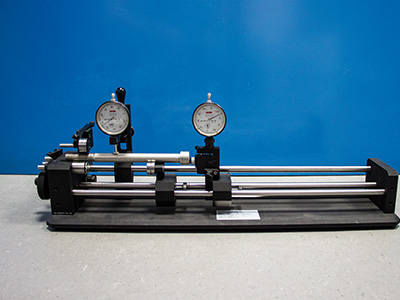

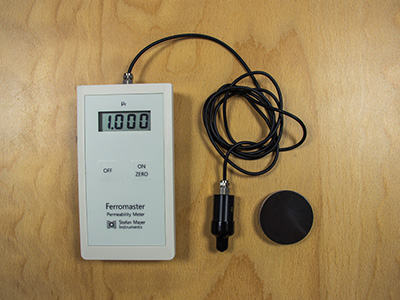

We work with state of the

art testing equipment

art testing equipment

We have successfully pursued a quality management system for a number of years now in order to guarantee our customers the highest quality products. Since 1996, Schäfer + Peters has been audited on an annual basis by DQS GmbH (German company specialising in certification and management systems). Currently we are successfully certified according to the latest standard DIN EN ISO 9001:2015. We also hold the GOST certificate for trade with Russia.

English

English Deutsch

Deutsch Français

Français Español

Español Português

Português Italiano

Italiano Русский

Русский Dansk

Dansk Svenska

Svenska Suomi

Suomi Hrvatski

Hrvatski Polski

Polski Română

Română Česky

Česky Türkçe

Türkçe